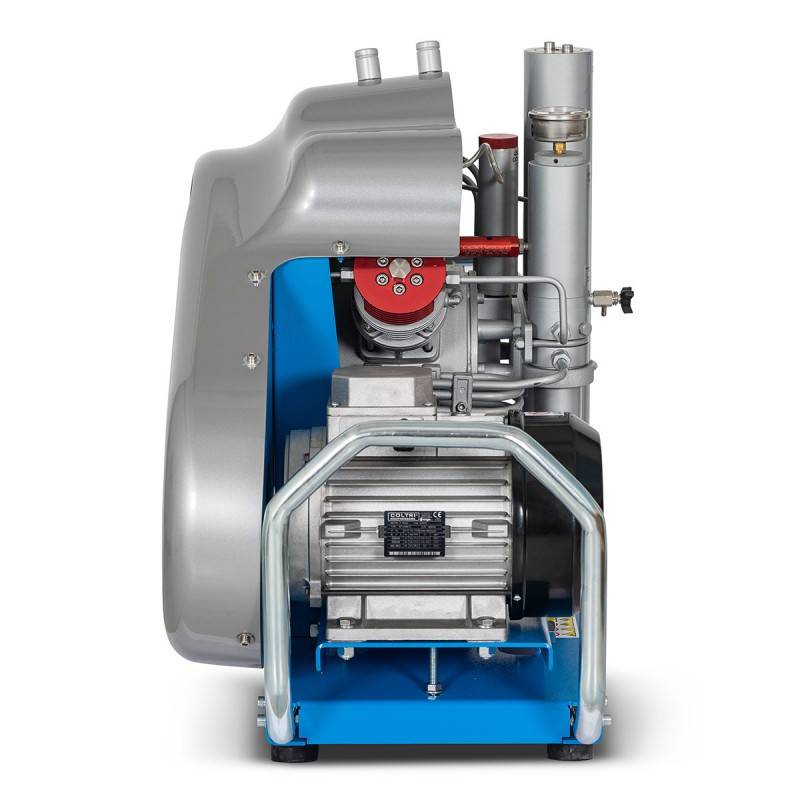

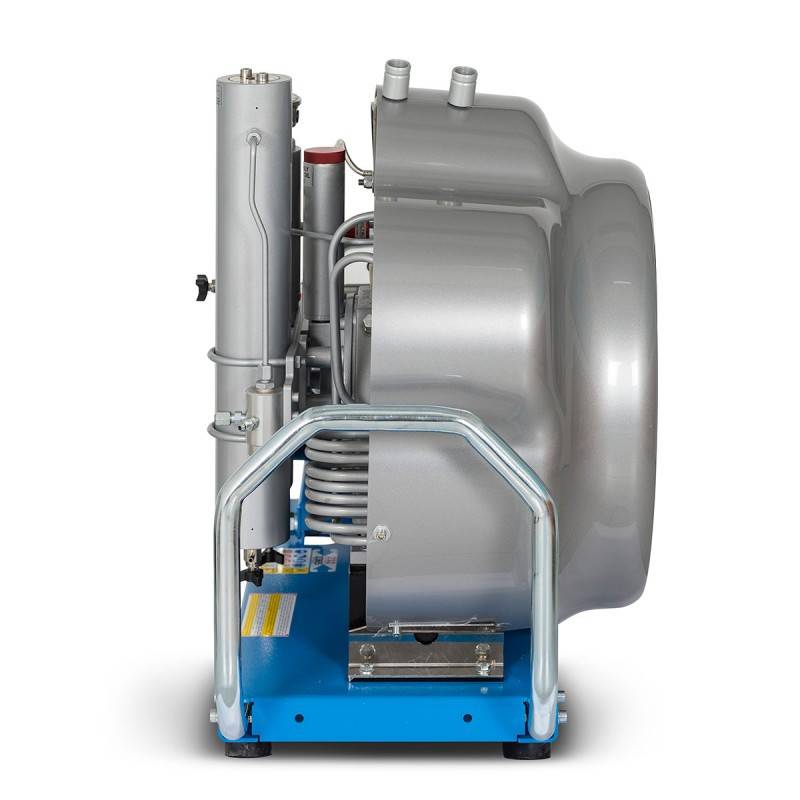

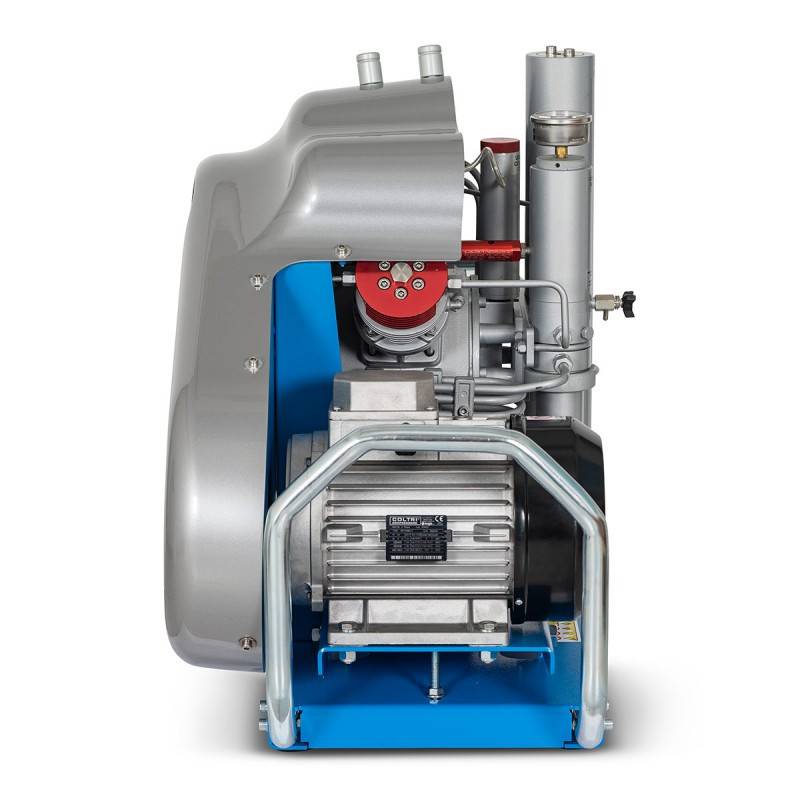

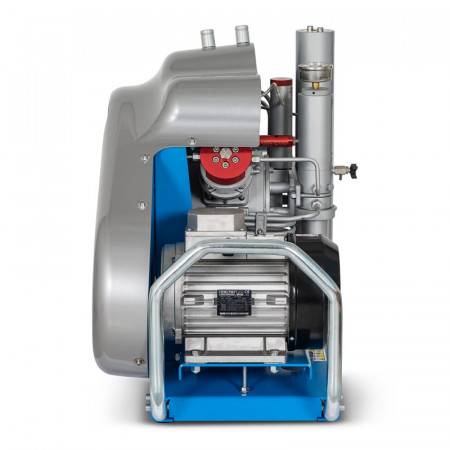

COLTRI MCH13/MCH16 and SMART 400V Three-phase compressor

Compressor COLTRI MCH13/MCH16 AND SMART

The SMART range is one of the most widely distributed machines in the world. Equipped with 2 flexible inflation outlets on the front, a drive motor, a robust compression block and a compact chassis with carrying handles. The chassis is suitable for transport and this version can be equipped with optional bleeders and automatic shut-off.

This version is suitable for users who do not have a three-phase power supply.

The SMART range is equipped with the MCH16 compressor block developed by COLTRI since the end of the 1960s and constantly improved to meet the requirements of performance, air quality and robustness required for use in the most severe conditions.

A proven compressor block!

The MCH16-V19 block is built to last. It has been tested under the most extreme conditions thousands of times around the world.

Adopted by the managers of the largest diving centers in Europe, Egypt, the West Indies, Polynesia and Asia for its reliability and ease of maintenance.

With more than 90,000 machines in operation in fire and rescue services in Europe, North America and Asia, it is capable of providing high load rates at operating pressures ranging from 330 bar up to 420 bar.

The COLTRI MCH16-V19 blocks are also embarked on merchant and naval vessels to meet the needs of onboard security services and divers.

Proven in the steel, automotive, plastics and petrochemical industries to meet production needs under severe conditions of use, it can also be used to meet the needs of specific industrial processes.

In service in the military operations of many armies around the world, its robustness and reliability have made it one of the French army's selection criteria when renewing its fleet of 150 compressors dispatched to the various theatres of operation around the world.

Quality of the compression block

The MCH16-V19 compression block is designed for professional applications. This is the essential component of the machine on which COLTRI has left nothing to chance.

All materials are machined in high energy performance light alloys for increased reliability.

The ground cylinders have undergone an ionic nitriding treatment, which results in a high surface hardness that provides high resistance to wear, friction, abrasion and seizure.

The crankshaft is mounted on robust SKF bearings that guarantee a long service life even at high temperatures.

The block is painted with a special paint that allows excellent heat dissipation while ensuring its protection against external aggressions in saline atmospheres. The paint makes maintenance easier when cleaning the cooling coils.

The 316L stainless steel interstage cooling coils are dimensioned to ensure optimal cooling and allow for increased cartridge autonomy.

The COLTRI MCH16-V19 block is designed to compress mixtures of air and NITROX up to 40% Oxygen.

A compact chassis!

The mechanically welded chassis of the SMART Efficient range promotes a good cooling flow and protects the user. The chassis integrates the electric motor, the compression block, the filtration system and 2 flexible outlets with inflation valve. Powder coated epoxy resin paint provides effective protection in hostile environments.

Filtration for Breathable Quality Air!

The compressor of the SMART range is equipped with several filtration systems to ensure an air quality in accordance with the requirements of EN 12021:2014.

The compressor block is equipped with cyclone separators on the 2nd and 3rd stages. The MAXIFILTER final filtration ensures filtration of oil, odours and water down to a dew point of -60°C.

An optional automatic start, purge and shutdown system is available as an option!

The compressor of the SMART range can be equipped as original equipment or retrofitted with a purging and automatic shutdown system.

The box allows the compressor to start and stop as well as to monitor the operating hours with its hour meter.

The automatic bleed system on the compressor is quiet and efficient. Its adjustable timer allows the purging frequency to be adapted to the ambient humidity level.

The drain block is designed to consume a minimum of air when draining condensate to maintain flow performance.

The automatic drain system is equipped with a condensate recovery system with silencers. It avoids the release of oily residues into the environment.

Data sheet:

- Height: 70 Cm

- Width: 100 Cm

- Depth: 46 Cm

- Weight: 100 Kg

- Working Pressure: 230, 300 or 330 Bars

- Energy: Single-phase electricity

- Sound Intensity In DB(A) At 1m: 79

- Compressor Usage: Professional and Association

- Direction Of Rotation Sensor: NO

- Nitrox 40% compatible: YES

- Automatic Purges: OPTIONAL

- Automatic Stop: OPTIONAL

- Rechargeable Filtration: NO

- Inter-stage pressure gauges: NO

- Number of Flexible Outlets With Faucet: 2

- Compressor Mobility: Mobile Compressor

Equipment :

- Mechanically welded frame with ABS casing.

- Manual purges

- Water and oil separator 2nd and 3rd stage

- Safety valves 1st, 2nd, 3rd stage

- MAXIFILTER filtration

- 2 flexible outlets at the front with DIN or ETRIER inflation valve

|

Compression group |

mch 13 |

mch 16 |

|

Reference |

sc000170 (400v-50hz) |

sc000230 (400v-50hz) sc000232 (230v-60hz) |

|

Debit |

235 l/min - 14,1 m³/h |

315 l/min - 18,9 m³/h |

|

Engine |

électrique triphasé |

électrique triphasé |

|

Operating pressure |

232 - 330 bar / 3 300 - 4 700 psig |

232 - 330 bar / 3 300 - 4 700 psig |

|

Power |

4 kw (400 v - 50/60 hz) |

5.5 kw (400 v - 50/60 hz) |

|

Dimensions (w x h x d) |

100 x 70 x 46 cm |

100 x 70 x 46 cm |

|

Approx. net weight |

95 kg |

105 kg |

|

Energy level Lpa acoustic |

80,7 db |

82,3 db |